TRACEABILITY

1️⃣ ALL ABOUT TRACEABILITY

📓 E-Book

🗞️ Articles

I. The new obligations of the AGEC Law

https://www.fairlymade.com/blog/les-nouvelles-obligations-du-decret-agec

https://www.fairlymade.com/blog/les-nouvelles-obligations-du-decret-agecII. Labels and certifications in the textile industry: a glossary of terms

https://www.fairlymade.com/blog/les-nouvelles-obligations-du-decret-agec

https://www.fairlymade.com/blog/les-nouvelles-obligations-du-decret-agec❓F.A.Q. - Traceability

We do lots of multi-sourcing. How does that work?

There are several solutions:

- Treat the two supply chains as two separate products, therefore two separate analyses.

- Analyze only the supply chain that has the highest volume e.g 80% of the product volume was using Supply Chain A and 20% used Supply Chain B

- Follow both supply chains for the same product (multi-sourcing).

In whatever case, the supplier must provide us with their Order Form (PO) numbers for the product or their lot numbers for the component.

Is it possible to operate on an order basis (PO) instead of product reference ?

Yes, we can certainly do traceability at PO level.

In that case, we will provide you as many traceability trees as POs you have declared. One PO = one analysis.

How do ADEME and PEF ratings take traceability into account - are brands obligated to trace production chains or is the material sufficient?

These methodologies are not yet complete, they are still under development.

However, the provisional versions we have had access to do not directly value a good understanding of product traceability. Traceability is valued through LCA (Life Cycle Assessment). If traceability is not properly established and defined, then higher data analysis will be used, which will penalize the product in terms of environmental impact.

How does Fairly Made® traceability work?

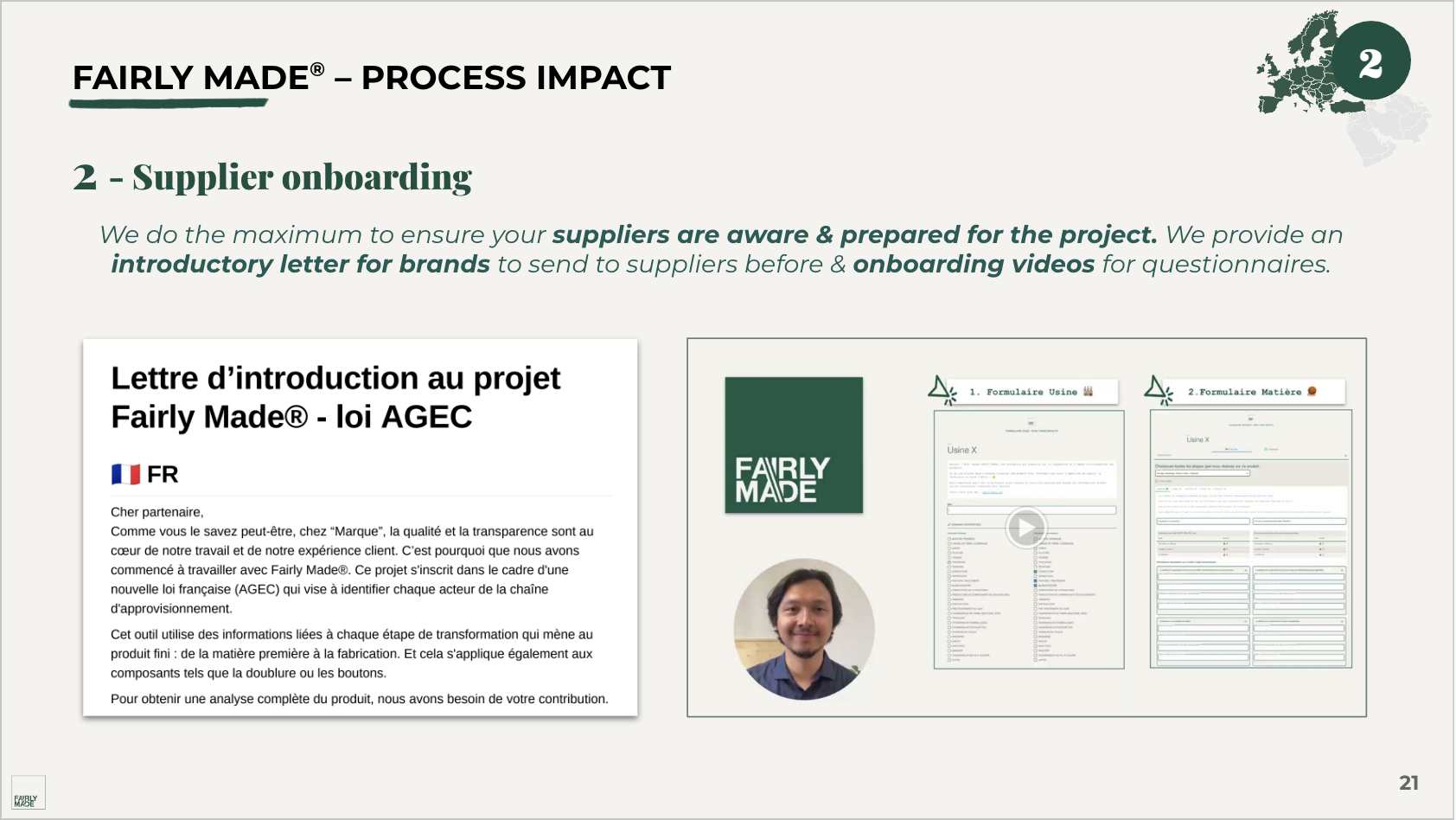

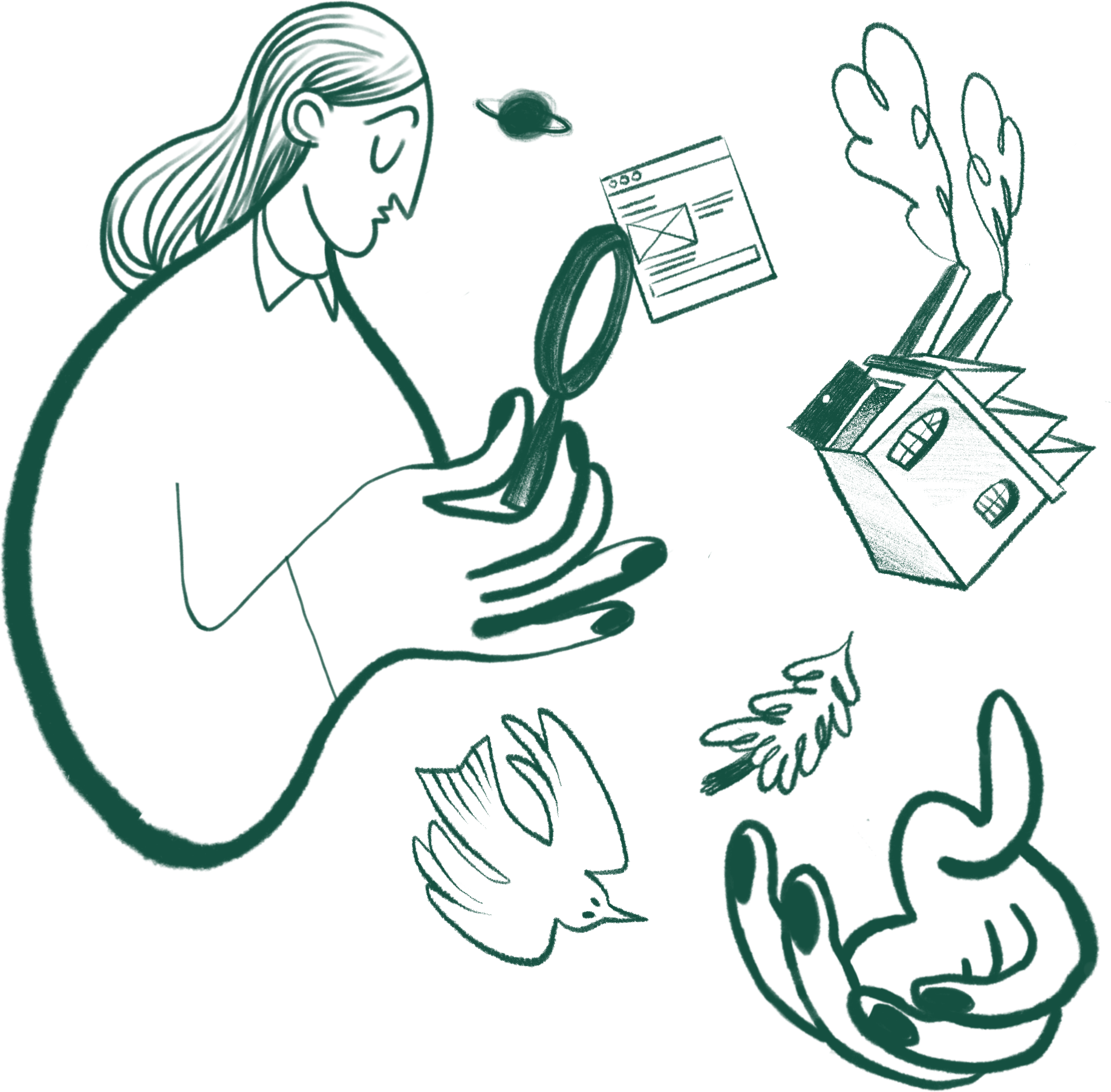

Thanks to our component and facility forms that we share with suppliers, we have all the information we need to establish the traceability of a product.

Starting from the information that brands push us about their known suppliers, we contact them, moving up the value chain, one step at a time.

Example: If a brand knows its garment manufacturer, we will question them to find out the weaver or knitter, then contact the weaver or knitter to discover the dyer, and so on, until reaching the raw material!

Could blockchain be a solution to ensure better traceability of production chains?

Currently, this technology does not ensure better traceability; its role is solely to guarantee non-modification after information declaration.

This is what we already do at Fairly Made®, without using blockchain. Therefore, we currently have no plans to integrate it into our approach.

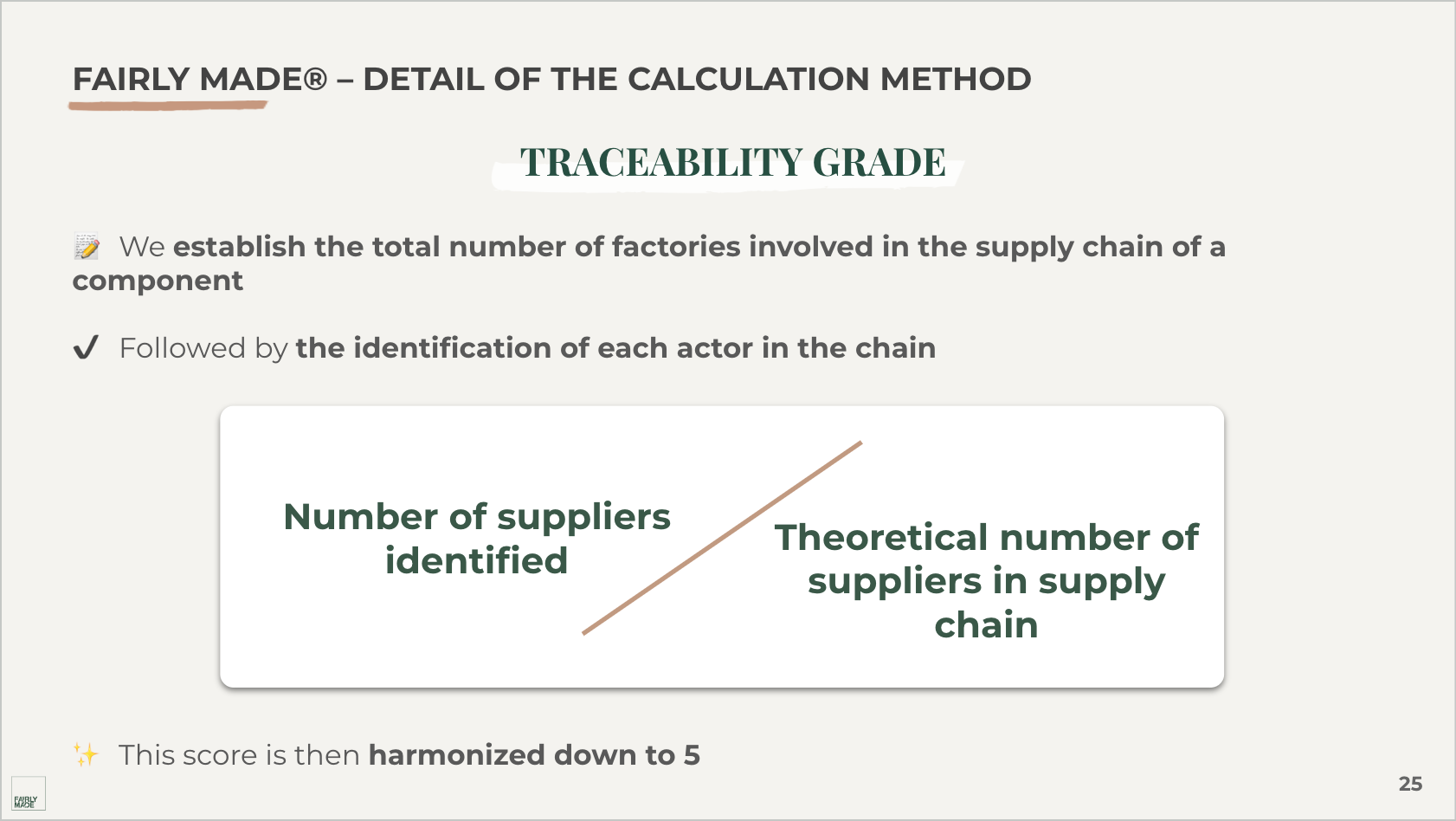

What does the traceability rating on the Fairly Made® platform represent?

This traceability rating indicates the number of identified factories during the data collection compared to the total theoretical number of factories existing in the production chain.

The rating is then converted into a score out of 5.

Each step, regardless of the supplier's rank or nature, has the same weighting.

How does Fairly Made® achieve the best traceability performance?

- Traceability analysts who are experts in textile engineering dedicated to projects.

- Unique tools and systems that allow Fairly Made® to efficiently collect information.

- Data collection forms designed for suppliers and created by industry experts.

- A database of +6000 known suppliers with whom we have already worked.

- Resources: videos,