SUPPLIER DATA COLLECTION

SUPPLIER DATA COLLECTION

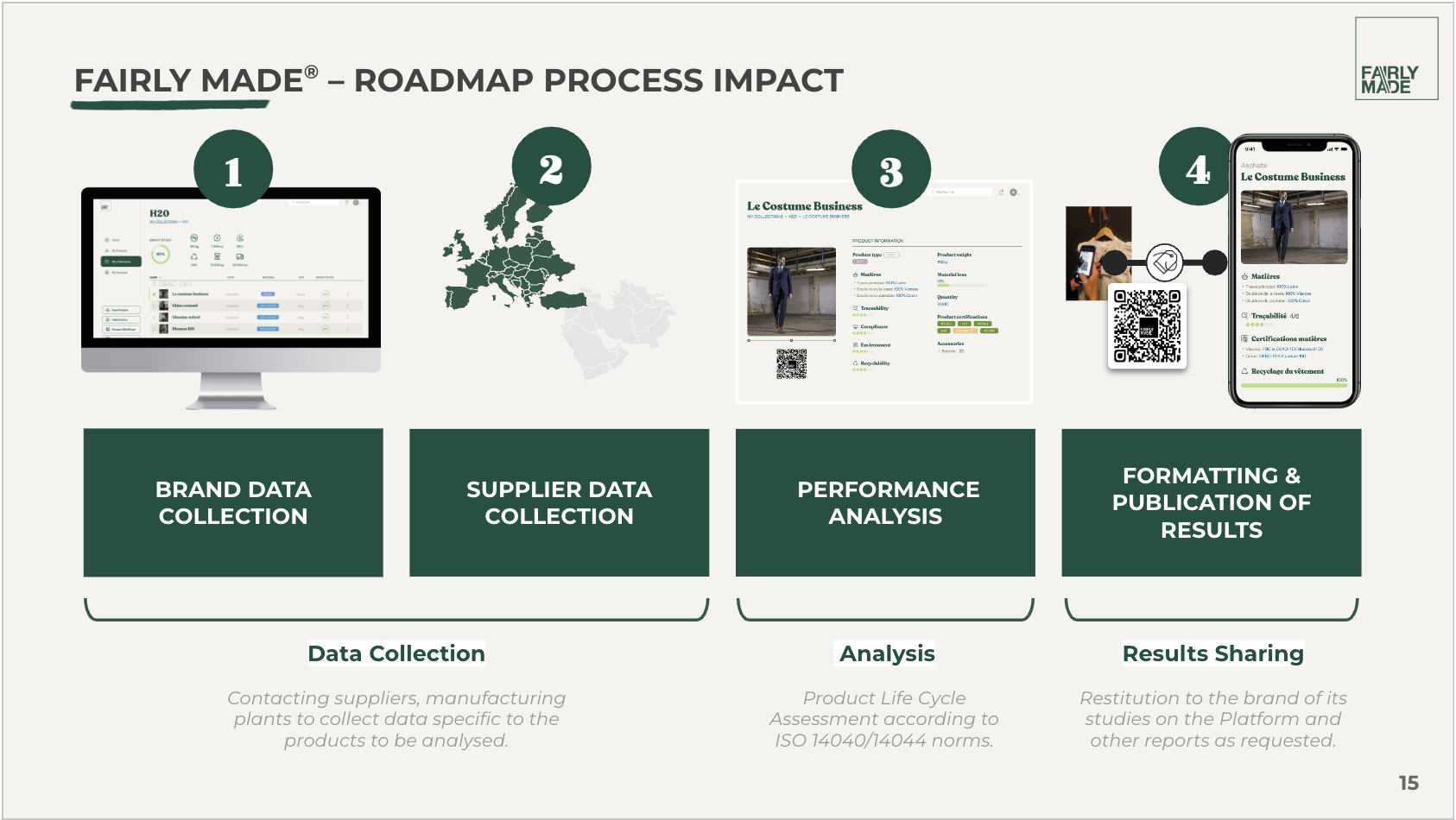

The Process

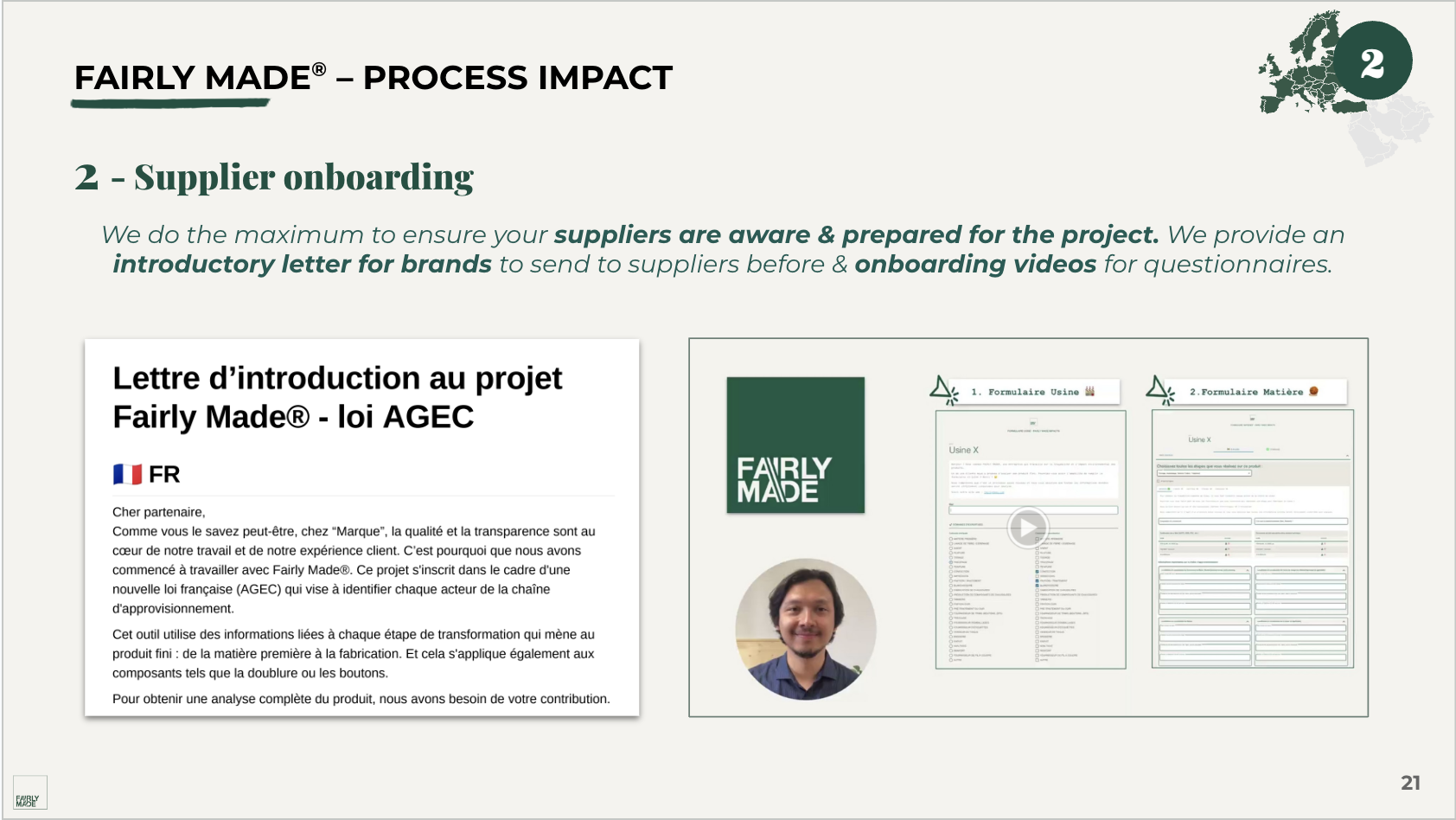

📮 Supplier Introduction Letters

Find in this section examples of Introduction Letters for our partnership addressed to your Suppliers.

🇫🇷 FR

Cher partenaire,

Comme vous le savez peut-être, chez “Marque”, la qualité et la transparence sont au cœur de notre travail et de notre expérience client. C’est pourquoi nous avons commencé à travailler avec Fairly Made®. Ce projet vise à identifier l'ensemble de la chaîne d'approvisionnement et mesurer l’impact environnemental sur une sélection de produits.

Cet outil utilise des informations liées à chaque étape de transformation qui mène au produit fini : de la matière première à la fabrication.

Pour obtenir une analyse complète du produit, nous avons besoin de votre contribution.

Dans les jours avenirs, vous allez recevoir de la part de Fairly Made® :

- Un formulaire usine : informations générales sur votre entreprises et ses bonnes pratiques.

- Un formulaire matière (si vous effectuez des modifications sur la matière) : informations spécifiques aux composants de différents produits.

Je vous serai extrêmement reconnaissant(e) si vous pouviez prendre quelques minutes pour remplir ces formulaires.

C'est très important pour nous, car connaître notre impact est la première étape pour le réduire. Et nous serions ravis d'emmener toutes nos parties prenantes avec nous dans cette aventure.

Un grand merci par avance pour votre aide et votre collaboration.

Bien à vous,

Signature

🇬🇧 EN

Dear partner,

As you may know, at “Brand”, quality and transparency are at the heart of our mission and our customer experience. That’s why we have started working with Fairly Made®. This project aims to identify the entire supply chain and measure the environmental impact on a selection of products.

Their solution harnesses product information related to each stage of the supply chain from final manufacturer to raw material.

In order to get a complete product analysis, we need your support.

In the next few days, Fairly Made® will send you :

- A factory form: general information about your facility and your practices

- A material form: specific information related to your production processes on each component

I would be extremely grateful if you could take a few minutes to complete these forms.

It's very important to us, because knowing our impact is the first step to reducing it. And we would be delighted to include all our stakeholders on this journey.

Thank you in advance for your help and collaboration.

Kind regards,

Signature

🇮🇹 IT

Gentile Partner,

Come forse saprai, da “Marca” la qualità e la trasparenza sono al centro del nostro lavoro e della nostra customer experience. Per questo motivo abbiamo iniziato a collaborare con Fairly Made®. Questo progetto mira a identificare l'intera catena di fornitura e a misurare l'impatto ambientale su una selezione di prodotti.

Questo strumento utilizza informazioni legate a ogni fase di trasformazione che porta al prodotto finito: dalle materie prime alla produzione.

Per ottenere un'analisi completa del prodotto, abbiamo bisogno del tuo contributo.

Nei prossimi giorni riceverai da Fairly Made® :

- Un modulo relativo alla fabbrica: informazioni generali sulla tua azienda e sulle sue best practice.

- Un modulo relativo al materiale (se effettui delle modifiche sul materiale): informazioni specifiche sui componenti dei diversi prodotti.

Ti saremmo grati se potessi dedicare qualche minuto alla compilazione di questi moduli.

È molto importante per noi, perché conoscere il nostro impatto è il primo passo per ridurlo e saremmo lieti di portare con noi in questa avventura tutti i nostri interlocutori.

Grazie in anticipo per il tuo aiuto e la tua collaborazione.

Cordiali saluti

🇨🇳 CN

亲爱的合作伙伴,

如你所知,在”Marque”,质量和透明度是我们工作和客户体验的核心。这就是为什么我们与Fairly Made®合作。这个项目旨在追溯整个供应链,并衡量产品的环境影响。Fairly Made帮助我们收集和分析产品的每个生产阶段的相关信息:从原材料到成品制造。为了获得对产品的完整分析,我们需要您的参与。

接下来,您将收到来自Fairly Made®的两张数据收集表格:

- 工厂信息表格:关于你的工厂及其良好做法的一般信息。

- 面料信息表格:关于不同产品部件的具体信息。

如果你能花几分钟时间完成这些表格,我们将不胜感激。这对我们非常重要,因为了解我们的供应链是优化影响的第一步。我们很高兴能带着我们所有的利益相关者一起开展这项项目。

感谢您的帮助和合作。

祝好!

This onboarding process for your Suppliers will allow us all to better start the data collection, by informing them about our partnership and your approach.

❓ F.A.Q.

Is onboarding done for suppliers?

Yes. It is mainly done to present the forms but also the legal landscape. All suppliers have access to an onboarding video, translated in their language to fill out the forms.

We also run regular webinars to explain the Fairly Made® solution, our process, the questionnaires and an update on the regulations.

How many supplier reminders are sent? When is the reminder sent?

We do not commit to a specific mailing schedule. Our contractual minimum is two emails per supplier. The first reminder is sent after 1 week.

Can a factory with material certification have different productions?

Yes. A factory can sell materials made from organic GOTS cotton and materials made from conventional cotton.

Example: Can the same factory with Eco-Vero produce certified viscose and another production of "low-end" viscose?

That is the difference between transaction certificates and scope certificates. Even with a scope certificate, we do not necessarily issue a TC for each production. However, certified and non-certified production chains must be well separated even if they are under the same roof.

What components are expected for AGEC?

Mandatory: Main component (RTW: "Main Fabric", Shoes: "Upper").

Mandatory: Component weight and product weight.

Optional: For AGEC, brands have the option to share more than the main component (fabrics, parts of the shoe, lining...). No trims.

Percentage claims are based on the sum of the component weight and the product weight.Example 1: Coat, only the main fabric

MAIN FABRIC (woven): 100% RECYCLED WOOL: 800g

Product weight: 1kg

"The product contains 80% recycled materials"Example 2: Coat, main fabric + lining

MAIN FABRIC (woven): 100% RECYCLED WOOL: 800g

LINING: 100% RECYCLED COTTON: 180g

Product weight: 1kg

980g of recycled material

Out of 1kg of product

"The product contains 98% recycled materials."

For components, what level of detail should be communicated?

We ask for at least the main component and encourage the brand to provide more details, starting with the linings.

The more information we have, the better.

Languages for questionnaires & platform? Presence of international clients?

Customer locations: Europe and the United States, and we are in discussions with brands from Canada and Asia.

B2B platform: currently available in English and French, but other languages will be added.

B2C product pages: any language desired by the brand.

Supplier questionnaires: French, English, Chinese, Italian, and Portuguese. We are constantly adding new languages based on the brand's needs.

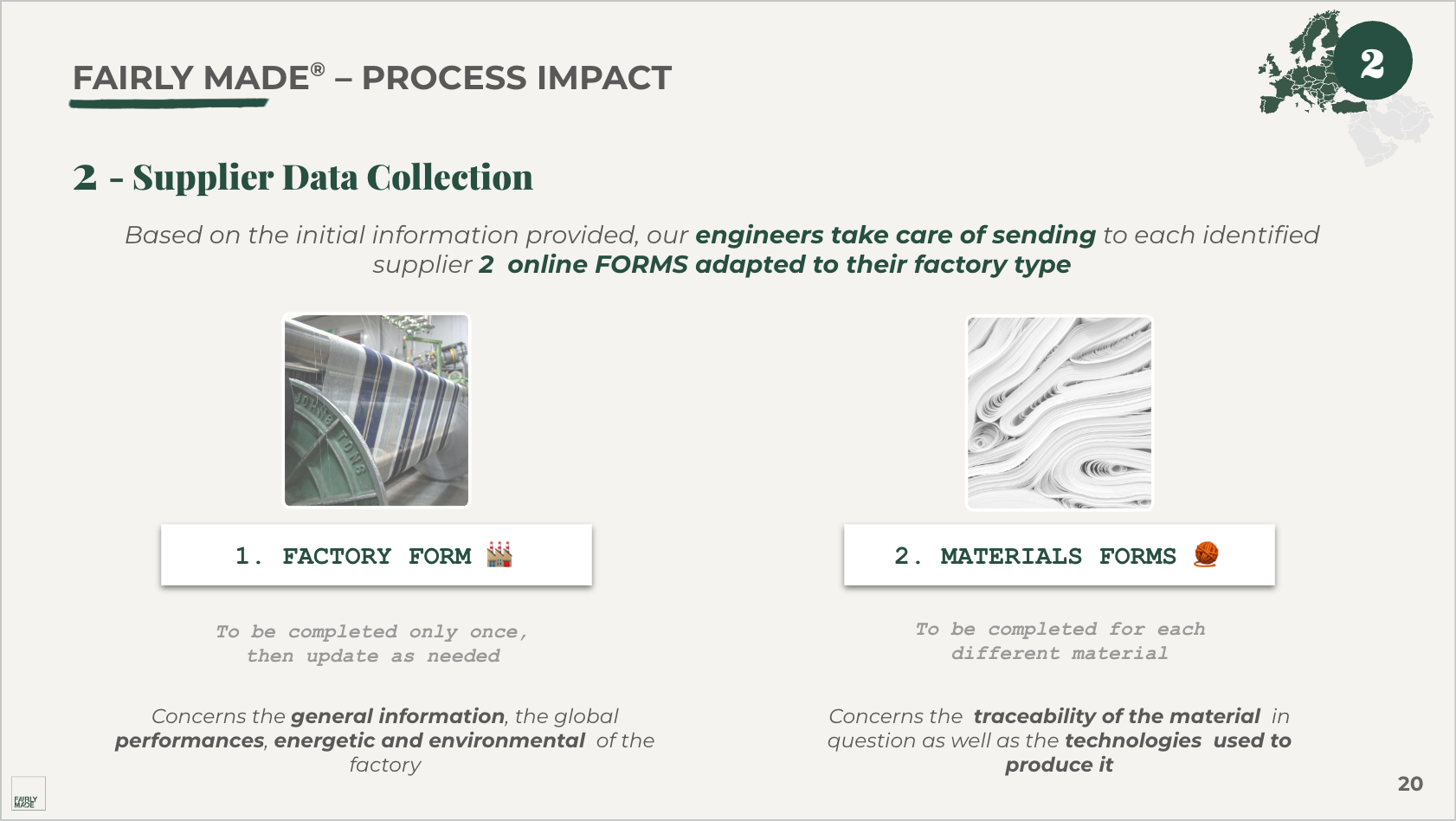

What are the questions in the Factory and Material forms?

Regarding the collection of "supplier" data, we send two forms:

- Factory Form (to be filled out once by the respective factory):

◦ We ask for general information about the factory (address, number of employees, etc.) to help you gain visbility on your supplier database.

◦

We ask for the factory's energy performance information to use in LCA (energy mix, heat type, etc.).

- Material Form:

◦ We ask the factory to declare the lower or higher ranks for each material they are familiar with.

◦ We ask for technical information about the production of materials (examples: spinning method, type of dyeing method, knitting techniques employed, etc.) to ensure the LCA results as accurate as possible.

- Factory Form (to be filled out once by the respective factory):

Do you verify the addresses of the factories?

We ask the factories and groups of factories for the exact addresses of the transformation factories, and we verify them in the PDF certificates.

.png)